Biodegradable plastics are emerging as an alternative to conventional plastics to address microplastic pollution. Unlike conventional plastics, biodegradable plastics are designed to break down over a faster timescale under specific conditions, potentially reducing long-term persistence in the environment. Although regulations are driving the market to adopt biodegradable alternatives, their role in tackling microplastic pollution can be contentious. Dr Shababa Selim, a senior technology analyst at market intelligence firm IDTechEx, explores whether biodegradable plastics can address microplastic pollution, previewing the findings of a new report.1

What are biodegradable polymers?

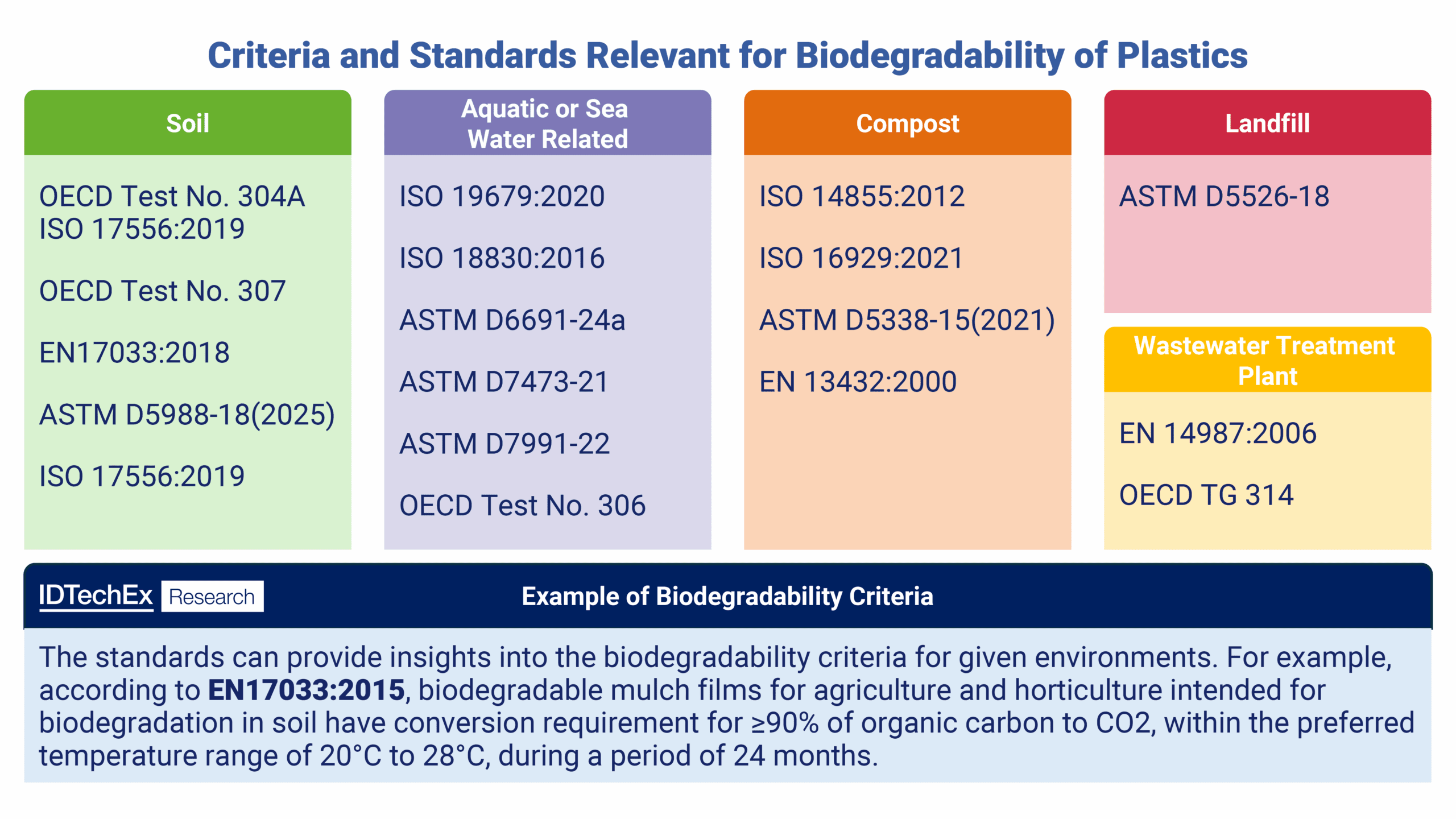

Biodegradation is the process of metabolizing polymers by microorganisms into water, CO2, and biomass. Interestingly, every organic polymer is generally biodegradable in isolation, and even the strongest polyolefins have evidence of biodegradation. However, this degradation would take place over many years and decades, rather than weeks to months. Therefore, the term “biodegradable” can be ambiguous unless the environment and time are specified. IDTechEx’s report Microplastics 2025: Regulations, Technologies, and Alternatives highlights several standards for testing biodegradability in a wide range of environments, such as soil, sea water, compost, landfill, etc. These can define criteria for biodegradability, for example according to EN17033:2018, biodegradable mulch films used in agriculture that are intended to biodegrade in soil require a ≥90% conversion rate of organic carbon to CO2 over a period of 24 months, within a temperature range of 20-25°C.

How are biodegradable plastics addressing regulations on microplastics?

Microplastics are used as functional additives in a wide range of products across various industries. These include consumer products, agricultural products (fertilizers, seed coatings), pharmaceuticals, paints and coatings, medical devices, and several others. In 2023, the EU’s REACH restriction on intentionally added microplastics was introduced, which is set to phase out microplastics across a wide range of products (e.g. rinse-off cosmetics, detergents, agricultural products, etc.) by 2035. However, its definition of microplastics states “non-biodegradable synthetic polymer particles”, which is prompting players to develop biodegradable alternatives.

A key example of this is in the agricultural sector, where microplastics are widely used as seed coatings, and as encapsulants for the controlled release of fertilizers and plant protection products. Improving the biodegradability of polymers used in agriculture is also being driven by other EU regulations. For example, EU regulation on fertilizing products ((EU) 2024/2788 and (EU) 2024/2790 amendments to Annex II of regulation (EU) 2019/1009) require materials used in technical additives to be biodegradable or soluble and chemically unmodified.

In light of this, several players such as BASF, Syngenta, Covestro, have launched biodegradable or microplastic-free seed coatings. However, developing biodegradable micro-encapsulants is more challenging. These can be considered as core-shell particles that encapsulate active ingredients for controlled release mechanisms. For conventional non-biodegradable polymers, the time period of controlled release of actives can be optimized by altering factors such as the thickness of shell walls, the size of capsules, the molecular weight of the polymer used, and crosslinking polymers to tune mechanical properties and structural integrity. However, manipulating these factors without compromising the biodegradability of polymers is not trivial. Nonetheless, startups such as Calyxia which is a spin-off of ESPCI Paris – PSL, University of Cambridge, and Harvard University are developing NaturaCaps™ for controlled release of agricultural actives, along with several other product lines targeting a range of applications.

Can biodegradable polymers avoid persistent microplastics?

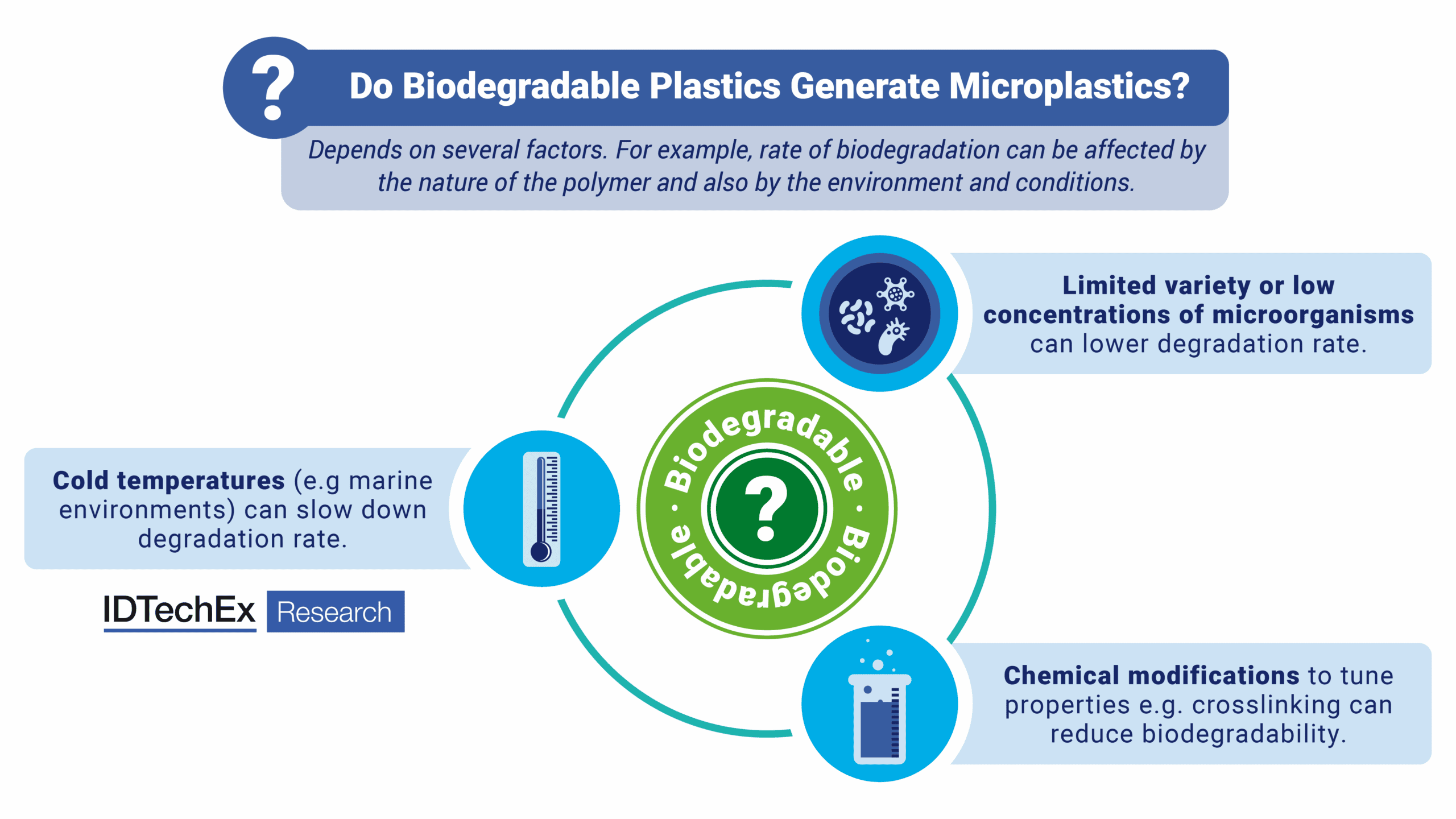

While there are biodegradable polymers that meet standards for biodegradability and compost-ability (e.g. Standard EN 17033), these products are generally more expensive and there are still concerns about the extent of biodegradability under real world conditions. Most biodegradable plastics require special treatment to biodegrade and compost, such as industrial composting facilities. Factors that can influence the biodegradation rate include temperature, the variety and concentration of microorganisms present, as well as exposure to UV light. For example, polylactic acid (PLA) is a well-known biodegradable biopolymer. However, in cold, oxygen-poor, and deep ocean environments, the degradation rate of PLA is significantly slower compared to controlled industrial composting conditions. Additionally, often chemical modifications are required to improve the mechanical properties and shelf-life of biodegradable plastic products which can compromise the biodegradability. All of this begs the question around the persistence of microplastics generated from products that are labelled as biodegradable.

Thus, without adequate plastic collection and sorting infrastructure for compostable plastics and industrial composting infrastructure, biodegradable plastics can still end up in landfills and marine environments and lead to environmental pollution.

Outlook

While biodegradable polymers are showing a lot of promise, the biodegradation process is affected by the environment and process conditions. In many cases, industrial composting is needed to break down biopolymers, which involves heating the biopolymers to a level where microbes can easily break then down. Without this, biopolymers often don’t degrade within a meaningful timeframe and cause the same environmental issues as conventional plastics. More research is needed in this area to identify and develop polymers that are biodegradable under meaningful environments and conditions.

Notes

[1] IDTechEx’s report Microplastics 2025: Regulations, Technologies, and Alternatives looks at biodegradable plastics as a solution, providing an assessment of key biodegradable polymers, highlighting the challenges around biodegradability, and the players at the forefront of developing biodegradable polymer-based solutions.