Researchers at EPFL have developed a model demonstrating how a novel graphene-based membrane material has the potential to reduce both the energy consumption and expenses associated with capturing CO2 from power generation and industrial facilities. This study is published in Nature Sustainability.

Carbon capture is becoming increasingly vital for industries that continue to rely on fossil fuels, such as the cement and steel sectors. Natural gas power plants, coal facilities, and cement manufacturing plants all emit significant quantities of CO2, and mitigating these emissions proves challenging without specialized capture systems. Currently, the majority of plants utilize solvent-based systems that absorb CO2; however, these systems demand substantial heat, necessitate extensive infrastructure, and can incur high operational costs.

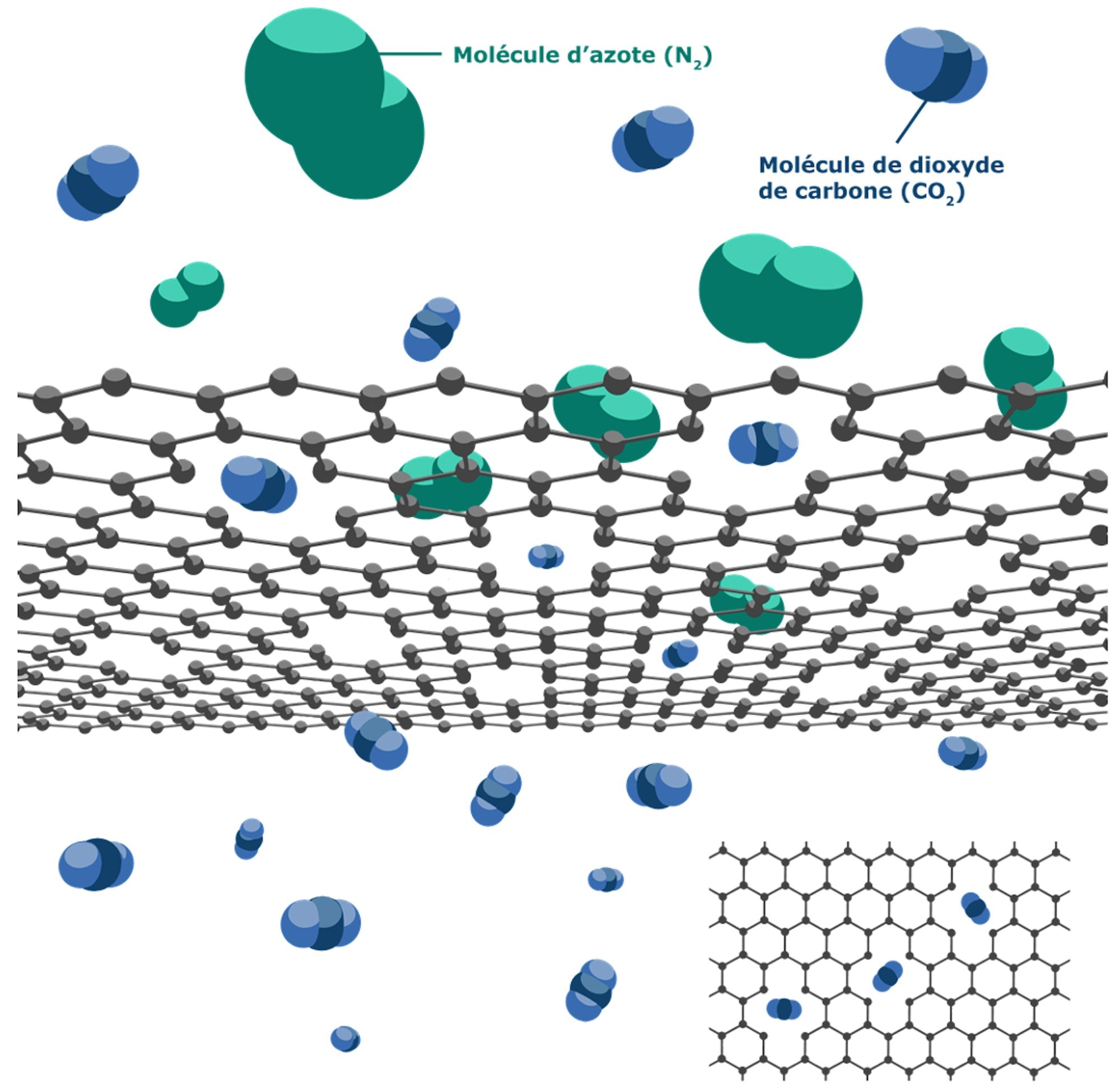

An alternative that is smaller and driven by electricity is referred to in the industry as a “membrane” system. This membrane functions similarly to an ultra-fine filter, allowing certain gases to pass through more readily than others, thereby isolating CO2 from the remaining flue gas. The challenge lies in the fact that many membranes experience a decline in efficiency when CO2 concentrations are low, a situation frequently encountered in natural gas plants, which restricts their applicability.

The recent study conducted at EPFL has examined the potential scalability of a novel membrane material known as pyridinic-graphene. This material consists of a single-layer graphene sheet featuring minuscule pores that preferentially allow CO2 to pass through compared to other gases. The researchers integrated experimental performance data with modeling tools that replicate actual operating conditions, including energy consumption and gas flow. They investigated various cost scenarios to assess how the material could perform when implemented in commercial facilities.

The research was conducted under the leadership of Marina Micari and Kumar Varoon Agrawal, who occupy the Gaznat Chair in Advanced Separations at EPFL. The study expands upon the group’s earlier work in creating scalable graphene membranes.

As we are scaling up the technology, it is important to understand the implications on reduction on energy use and cost of carbon capture in the diverse sector of carbon capture. This work address this.

Kumar Varoon Agrawal, Advanced Separations, EPFL

Modeling Shows Where the Membrane Performs Best

The team conducted tests on various graphene-based membranes, including the pyridinic-graphene membrane, across multiple plant configurations to evaluate their performance under real-world conditions.

For natural gas power plants, a three-step process that begins with the enrichment of the CO2 stream demonstrated promising costs, approximately USD 80–100 per ton, with optimal cases achieving as low as USD 60–80. This is significant as membranes typically face challenges with such dilute flue gas.

In coal-fired power plants, where CO2 concentrations are elevated, the membrane’s excellent CO2/N2 selectivity reduces energy consumption and lowers costs to the range of USD 25–50 per ton. Cement manufacturing facilities exhibit higher oxygen levels in their flue gas, complicating selectivity; however, the membrane still achieves comparable cost ranges and maintains stability across the various scenarios assessed. Throughout all three sectors, the membrane’s high permeance minimizes the necessary surface area, thereby contributing to a reduced footprint for a complete capture system.

The research indicates that pyridinic-graphene could provide a compact and potentially economical alternative to solvent-based capture methods once it is scaled up. It also highlights areas for potential enhancement, particularly regarding its capacity to differentiate CO2 from oxygen in cement flue gas.

Journal Reference:

Micari, M., et al. (2025) Energy- and cost-efficient CO2 capture from dilute emissions by pyridinic-graphene membranes. Nature Sustainability. DOI:10.1038/s41893-025-01696-5.